With the continuous development of Skystone, We have been providing our best product and service to our customers. We embrace the future full of optimism and also hope to open a new hopeful chapter with each customer.

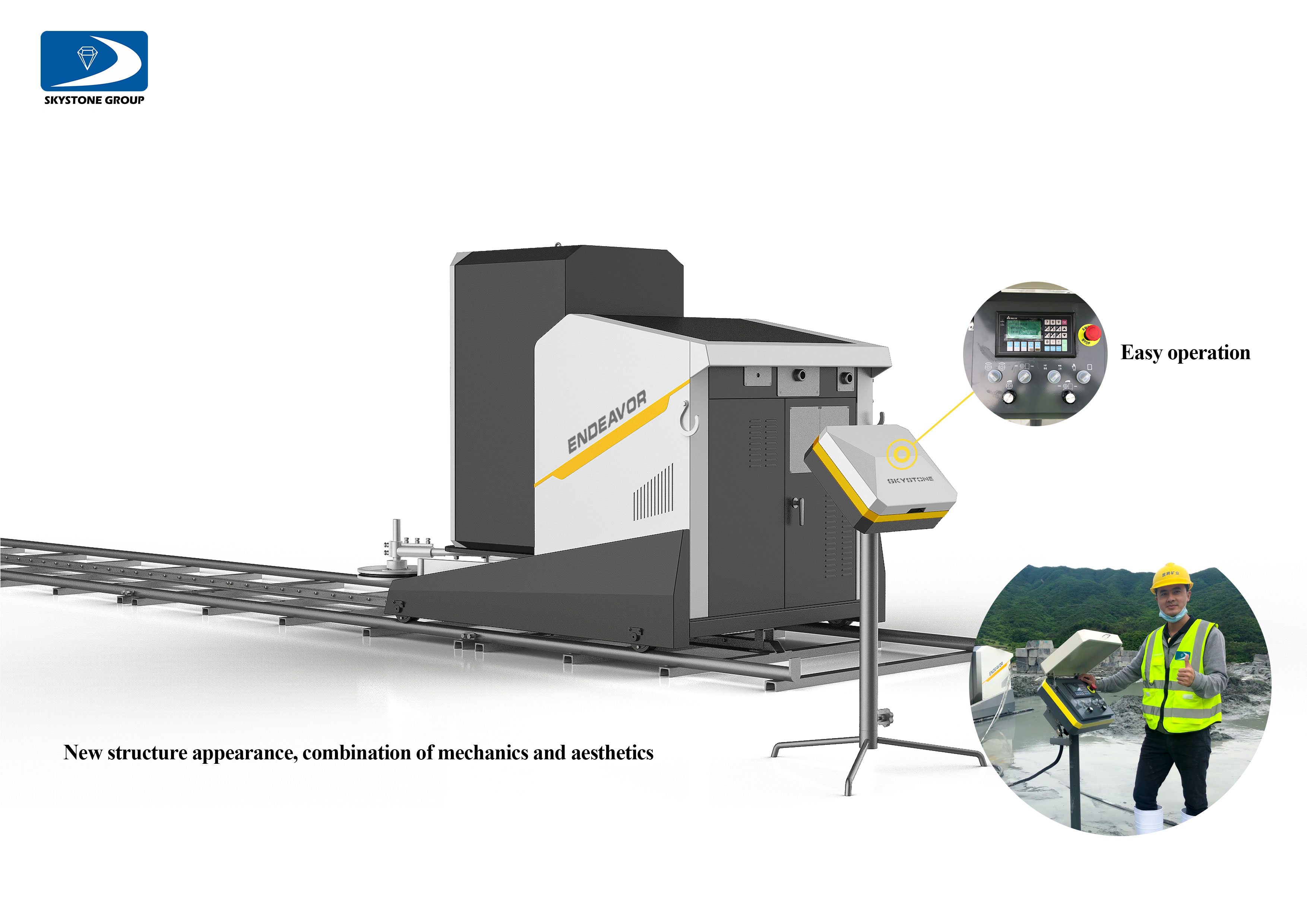

Skystone diamond wire saws now are easier to operate, which is inseparable from the extensive application of automatic control engineering in our diamond wire saws. When the wire saw machine is in automatic mode, the traveling is under closed-loop controlled.

The traveling motor with encoder and PG vector controlled; the high-precision sensor feeds back the real-time traveling speed data to the PLC, and the PLC can adjust the traveling speed according to the cutting current of the main motor: when the cutting current is too high, out of safety and to prevent the risk of wire breakage, the traveling will be appropriately reduced. When the cutting current of the main motor is within the set value, under this condition, the PLC controls the traveling with the most efficiency and smoothness.

At the same time, the sharpness of the diamond wires can affect the cutting efficiency of the machines greatly. By using our diamond wires, our machine can cut with the fastest efficiency;

Through our machine R&D team's research, rich cutting experience, and cutting data collection from quarries around the world, the automatic control mode of our machine can ensure the efficiency and lifetime of the diamond wires can show the best performance.